If you are looking for durable and reliable caster wheels for your AGV, you have come to the right place. This article will give you an overview of the different types of casters, including stainless steel and rigid ones. We’ll also look at their maintenance and durability. So, what’s the best type of AGV casters for your needs? Here https://www.casterwheelsco.com/ are some tips to help you choose the right one.

Table of Contents

Stainless steel casters

The newest advancement in automatic guided vehicle caster wheels is a suspension system. AGV suspension systems allow the vehicle’s center of gravity to remain stable even when navigating over uneven surfaces. The pivoting arms isolate the load supporting structure 140 from the wheels. This system also decouples the chassis 102 from the arms, ensuring a stable, center-of-gravity-adjustable AGV.

Among all the AGV casters wheels available in the market, a shock absorber AGV wheel is the best. This wheel incorporates a dual sealed precision ball bearing system, which provides high-speed performance and low-drag force. Its double-wheel structure allows easy steering and maneuverability, and it has superior environmental protection. The wheels are durable and can withstand the harshest terrain. If you’re looking for high-quality wheels for your industrial AGVs, make sure you consider a stainless steel suspension AGV wheel.

Rigid casters

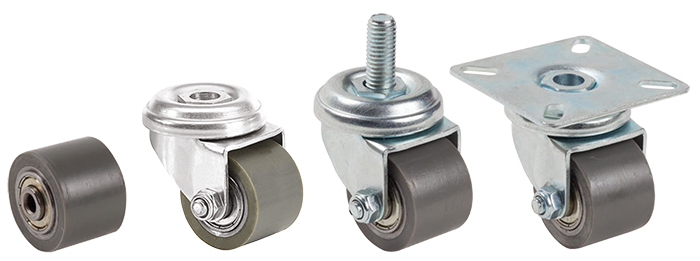

An AGV is typically equipped with two sets of caster wheels to facilitate movement. These casters are mounted on the caster frame and support at least part of the AGV’s weight. When the drive wheels are retractable, the entire weight is supported by the casters. Each caster wheel rotates and swivels freely along its axis. The casters are spaced apart by about 20 mm.

The caster wheels are attached to the drive axle through a coupler. The first set is connected to the front axle by the suspension rocker and weighs about 300 lbs. The second set is attached to the front axle via a coupling. These two sets are able to pivot on the axle. The AGV’s caster wheels may be mounted on the chassis or on a floating axle.

Durability

The durability of suspension AGV caster wheels is important for a variety of reasons. They are not only ergonomic, but they also enable the AGV to move easily and smoothly on hard facility floors. AGVs are typically able to carry loads of up to 20,000 pounds, making the wheels an important component of an AGV. They also help to prevent repetitive strain injuries, because the wheels can easily absorb energy during transportation and reduce the force required to push the vehicle.

Maintenance

Proper maintenance of suspension AGV caster wheels is vital for their smooth operation. Ensure that all casters are lubricated and check for any damage regularly. Damaged wheels will likely fail sooner rather than later. Also, they must be replaced in time to avoid compromising the transit process. By following these maintenance tips, you can minimize the downtime of your suspension AGV. Listed below are some of the most important considerations when maintenance of suspension AGV caster wheels.

First, clean AGV caster wheels regularly. Dust and dirt can impede their movement, causing a delay in transit. To restore smoothness, lubricate the caster wheels. Any debris, dirt or obstructions can wear away the caster wheels and cause transit delays. You should also check the caster wheels for cracks or debris to extend their lifespan. AGV wheels can be worn away by repeated exposure to these elements.